|

| October 10, 2017 | Volume 13 Issue 38 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

World's largest all-composite aircraft structure optimized with Collier's HyperSizer software

Stratolaunch aircraft rolling out of the hangar in spring 2017. [Image courtesy: Stratolaunch Systems Corp.]

When the 385-ft-wide Stratolaunch aircraft rolled out of the Mojave, CA, Air and Space Port hangar this spring in preparation for ground testing, it was a clear example of how far the design and manufacturing of composite materials have progressed in recent years. Last month, the first phase of engine testing on the aircraft's six Pratt & Whitney turbofan engines was completed.

The world's largest aircraft by wingspan (wider than a football field is long) is almost entirely fabricated from composite materials, which provide light weight, high stiffness, and strength characteristics that are increasingly in demand in aerospace, automotive, sports, medical, and industrial fields.

The Stratolaunch aircraft is the brainchild of Stratolaunch System Corporation founder Paul G. Allen (also co-founder of Microsoft). It has two fuselages connected by a giant single wing and is powered by six engines that will enable it to take off from a runway carrying a payload up to 550,000 lb. At the cruising altitude of a commercial airliner, the Stratolaunch air-launch platform will release the space launch vehicle payload and return to the airport for reuse. The first launch demonstration is anticipated to take place as early as 2019.

Collier Research's HyperSizer optimization software was used extensively by manufacturer Scaled Composites to optimize the aircraft's composite fuselage and wing structure. HyperSizer, the first software package to be commercialized out of NASA, has been employed on a wide variety of aerospace and other industry projects fabricated with composite or metallic materials. The software automatically performs design, stress analysis, and sizing optimization, typically reducing the weight of structures by 20 to 40 percent.

"To ensure the most efficient use of materials in an all-composite structure of any size requires effective employment of design and manufacturing optimization tools from the very earliest stages," says Craig Collier, Collier Research president.

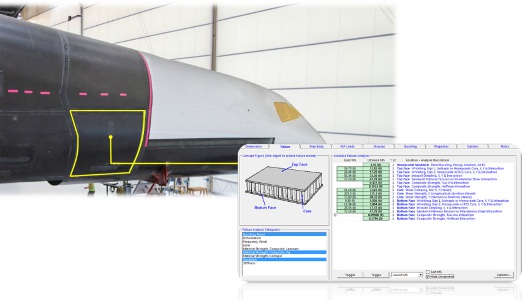

Early construction phase of one of the two fuselages of the all-composite Stratolaunch aircraft and (inset) a screenshot showing a HyperSizer analysis of the structure. [Images courtesy: Stratolaunch Systems Corp.]

For the massive Stratolaunch wing, deflection limits were a significant factor to be taken into account. The panels of the dual fuselages were sized for strength, stability, and honeycomb sandwich failure modes. By using HyperSizer, the stress team had access to a comprehensive set of automated failure analyses that included rapid free-body analysis; discrete laminate sizing; ply-based composite failure analysis; honeycomb sandwich analysis methods such as wrinkling, core shear, flatwise tension, and intracell dimpling; and scripting API to push in loads from Excel spreadsheets.

Collier says he is seeing continuing evolution in the integration of the toolsets used for composites design and manufacturing. "HyperSizer software can provide insight into how producible a structure is and whether there might be any manufacturing issues," he says. "It can incorporate laminate fabrication preferences in early-stage design thought. Ease of manufacturing is becoming a major influence with strength design of laminate structures."

Source: Collier Research Corporation

Published October 2017

Rate this article

View our terms of use and privacy policy